Production equipment

Thermal cutting:

CNC cutters for plasma-oxygen cutting:

- sheet 2500 x 12000 mm, thickness of 200 mm

- sheet 2000 x 6000 mm, thickness of 200 mm

Plastic working:

- Bending brake – Qmax = 600 t, l max = 6100 mm

- Hydraulic press – Qmax = 280 t

- Four-high rolling mill, l = 3100 mm, =20 mm

Machining:

- Boring machine X = 6000 mm, Y = 3500 mm, Z = 2100 mm, table 18 t, automatic tool store – 60 pcs

- Turning centre DMG CTX Beta 500 with bar feeder IRCO BREUNING, d = 65 mm

- Turning centre HAAS SL-10 THE

We have anti-corrosion process lines at our disposal, composed of:

- Shot-blasting chamber with dimensions 15 x 5 x 5m with shot separation devices for 2 work stations

- Paint shop with dimensions 12 m x 80 m x 6 m

- Coating and drying cabin 16 m x 5 m x 5 m

CNC plasma - oxygen cut-off machine Jantar 2 by the company Eckert

- aimed for cutting with oxygen and plasma burner

- bench dimensions 2500 x 12000 mm

- cutting thickness 200 mm

Broad-band grinding machine (deburring machine) for sheets Costa MD7 CRR 1650

- CNC control

- usable width 1650 mm

- treated thickness 0,5 – 160 mm

- feeding table with element feeding speed 0,3 – 6 m/min

Piercer Hydracrop

Maximal cutting parameters

- flat bar: 450×15; 300×20

- angle bar (cutting without deformation) 130x130x13

- angle bar (cutting with slight deformation) with the application of a special knife: 150x150x13

- round and square bars 45 mm

- holes (piercing) 40×14

Piercing machine VERNET BEHRINGER PG 83 S CNC

Detail working dimensions:

- at least 80 mm x 80 mm x 3 mm

- at most 1250 mm x 750 mm x 20 mm

Piercing ∅ max 32 mm

- 3 tools (possibility of marking)

- ∅ min. 8 mm, sheet with a thickness of 8 mm

- ∅ max. 32 mm, sheet with a thickness of 20 mm

Pressure force 80 t

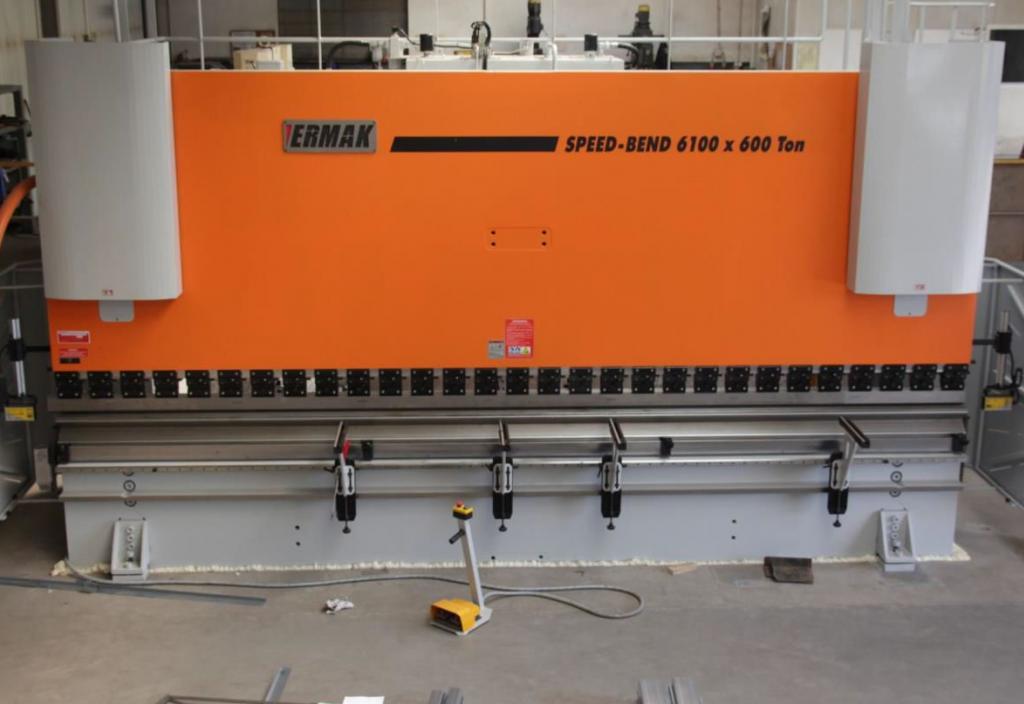

Numerically operated bending brake ERMAKSAN

Technical data:

- pressure – 600 tons

- working length – 6100 mm

Four-high rolling mill CNC Sahinler 4R HSS 30 - 350

Technical characteristics:

- 7-axle control NC EasyView 10”

- working length of rolling – 3100 mm

- central rolls 350 mm

- side rolls 260 mm

Bench boring machine TOS WHQ 13 CNC

- automatic tool store – 60 pcs

- axis X = 6000 mm

- axis Y = 3500 mm

- axis Z = 2100 mm

- CNC turntable, axis B, type S18 – 18 t, 2000 x 3000 mm

- control HEIDENHAIN iTNC 530

CNC turning centre with bar feeder CTX Beta 500 Gildemeister

chuck – centre lathe automatic machine

- with bar feeder Irco Breuning L = 3000 mm

- maximal bar rolling diameter – 65 mm

- automatic unloading of steel onto the belt

- 12-position tool head with power-driven tools

- maximal rolling diameter in lath centres – 410 mm

- maximal speed of rotation 5000 rpm

CNC turning centre Haas SL-10

- maximal rolling diameter 279 mm

- maximal rolling length 356 mm

- maximal bar rolling diameter 44 mm

- max. spindle rotation 6000 rpm

Shot-blasting chamber

- hot-blasting chamber with dimensions 15 x 5 x 5m with shot separation devices for 2 work stations.

Coating and drying cabin

Technical parameters of the cabin:

- internal length – 16000 mm,

- internal width – 5000 mm,

- internal height – 5000 mm,

- door height – 4500 mm,

- door width – 4000 mm.

Airless spraying units Xtreme by the company GRACO

High-pressure pneumatic airless sprayers Xtreme NXT of the company Graco ensure strength and long time of operation, contributing to increase in yield. Designed for work with a new pneumatic motor NXT of the company Graco, Xtreme NXT sprayers are well-known for better capacity and durability than other sprayers in their class. They easily deal with the hardest protective coatings and anti-corrosive materials.

CNC Belt Cut-off Machine Ergonomic 290.250 GANC

| Cutting angles | ||||

|---|---|---|---|---|

|

|

|

|

|

| 0 ° | ø 250 mm | 280 x 230 mm | 290 x 230 mm | 250 x 250 mm |

| P 45 ° (+ 45 °) | ø 200 mm | 220 x 80 mm | 190 x 230 mm | 200 x 200 mm |

| L 45 ° (-45 °) | – | – | – | – |

| P 60 ° (+ 60 °) | ø 110 mm | 120 x 80 mm | 120 x 100 mm | 110 x 110 mm |

| L 60 ° (-60 °) | – | – | – | – |

Belt Cut-off Machine economic 510.320 DG

| Angle | ||||

| 0 ° | 345 | 515 x 220 | 150 x 370 | 340 x 340 |

| P 45 ° | 340 | 360 x 120 | 255 x 340 | 310 x 310 |

| L 45 ° | 340 | 370 x 120 | 130 x 370 | 325 x 325 |

| P 60 ° | 240 | 240 x 120 | 120 x 340 | 220 x 220 |

| L 60 ° | – | – | – | – |

Belt Cut-off Machine Ergonomic 275.230 DG

| Angle | ||||

| 0 ° | 230 | 275 x 200 | 250 x 230 | 230 x 230 |

| P 45 ° | 190 | 190 x 160 | 180 x 230 | 190 x 190 |

| L 45 ° | 170 | 185 x 100 | 90 x 230 | 150 x 150 |

| P 60 ° | 120 | 120 x 85 | 120 x 85 | 85 x 85 |

| L 60 ° | – | – | – | – |

Cut-off Machine Ergonomic 320.250 DGH

Cutting angles:

|